-

Canopy Management

- » DF Pneumatic Leaf Remover

- » C-305 Independent Hydraulic Power Unit

- » CM-FF – Orchard Topper

- » CM-SF – Synchronized Bar Mower Topper

- » CM-SD – Synchronized Double Topping Machine

- » CM-SDT – Simple Synchronized Double Topping Machine

- » CM-SNU – Over-the-Row Topping Machine

- » CM-SNE – Electric and Hybrid Synchronized Topping Machine

- » CM-B – Basic Topping Machine

- » CM-SN New Model Synchronized Topping Machine

- » CM-S Synchronized Topping Machine

BFM innovation keeps pace with changing cultivation techniques

On 17/04/2025

Comments Off on BFM innovation keeps pace with changing cultivation techniques

The innovation of BFM in step with the change of cultivation techniques

[ns_postMeta]

In the last two decades, the seasons have changed a lot and this has as a consequence a radical change in the techniques of cultivation. The team BFM studied solutions to help as much as possible the vegetation in progress looking for contravening the damage caused by climate change.

Between the cultivation techniques that have changed should be recorded in the defoliation of the screw, a widespread practice in recent years and especially in the northern areas of our Country, who for a long time, it was performed by hand, but that innovation has mechanized. In this article we explain the importance of this operation.

The defoliation of the screw

over the period of pre-bud burst, which runs from January to march prepare for the vegetative growth between the end of April, beginning of may. In this phase, often used in treatments based on sulfur, but the trend is always more oriented to assist in the use of chemicals for the protection of the soil and the vegetation.

For this reason, we are implementing some of the practices of preparatory such as defoliation, also called the stripping of the screw, with the intent to preserve the good health of the plant and at the same time create a balance that climate change, with its peaks of drought and high temperatures has sadly changed.

Through theelimination of the leaves adjacent to the cluster, it tries to penetrate the light in such a way that the grape accumulations by means ofsolar radiation more compounds, and this will help in a natural way to stimulate the synthesis of it arising.

Benefits of defoliation of the screw,

The process that implements the exposure of the grapes to the light goes to strongly affect the quality of the grape in terms of the flavors that can develop, and other metabolic processes associated with it.

The ventilation comes from the pruning of the plant and promotes growth and creates a micro-climate that prevents the formation of fungal diseases. It is shown that defoliation make a substantial reduction of chemical treatments , pesticides and pests implemented on the vine.

It is very important that the pruning of the plant is performed in an optimal manner in order to achieve a effect and indirect of the grain, to avoid negative consequences such as the increase of the temperature of the tissues that if exceeds a certain limit, blocks the metabolism of the grape, or the dehydration of the bunch.

The methodology with which it is executed the defoliation of the screw varies depending on the vineyard-to-treat and the climatic situation of the season.

Characteristics of the defogliatrice BFM

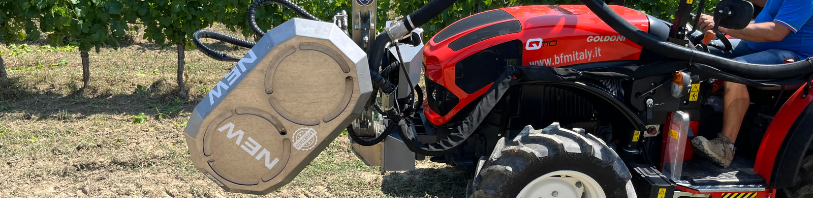

The ideal machine to promote the ripening of the grapes through the stripping of the screw is the defogliatrice BFM who, with his concept, versatile and lightweight ensures accurate and fast.

Ideal for all types of vineyard and orchard, with the ability to be composed in multiple versions.

As all the machinery of the range BFM is characterized by a high strength , made all in stainless steel. This ensures the durability of the machine over time.

The defogliatrice BFMproduces compressed air pulse or a jet of high pressure air that allows, in addition to the removal of the leaves, and also to get rid of spider webs-the principle of possible fungal diseases and bacteria. In this way, there is a protection of the bunch and less maintenance than other types of defogliartici require.

Conclusion

Even in this occasion, the BFM has demonstrated the highest standards but, above all, knowing how to stay pace with the innovation that the world demands.

The design, study and development of machines BFM follow an optical bio for the protection of the planet. Seeking to improve its machinery is looking to support this view.

The machines BFM right from the beginning, have always been designed with a mechanical functionality minimizing the intake plumbing. This has as a consequence a lower risk of pollution.

The team BFM is at your disposal for all your questions and to help you to orientate yourself better in the choice of the machinery that is right for you. Please contact us for advice tailored to you based on your specific needs.